Hello everyone, my name is Andrew Kistler, and I am spending my summer in Golden Colorado at Colorado School of Mines. For the next seven weeks, I will be working in the M3 Robotics lab with Dr. Andrew Petruska as well as some graduate and undergraduate students.

This week we still continued to have issues with the limit switches on the gantry carriage. We did discover the issue though. The reason the limit switch is communicating that it’s being pressed multiple times despite only being pressed once is due to electromagnetic interference. The EMI is caused by other components on the carriage that draw a large amount of power. What is strange about this issue, though, is that all of these cables are shielded to avoid this issue, and yet we are still having issues with EMI.

Despite the continued issues with the limit switch, we actually were able to get the carriage moving. In order to do this we made the software basically ignore the signals coming from the limit switches. That is only a temporary fix just so we can get it moving. We hope to find a more permanent solution in the coming weeks.

This week we, unfortunately, had to largely disassemble the gantry. This week the lab had a meeting with OSHA (The Occupational Safety and Health Administration). They had issues with our gantry system having a large amount of exposed wood as it is considered a fire hazard. Because of this we were faced with two options: replacing the wood with a fireproof material or painting the wood with fire-resistant paint. We chose to try and paint the wood, but in order to do this we have to remove practically everything from the gantry. We have not yet finished dissembling the gantry, but that should be done early next week so that we can begin the painting process.

I also was finally able to get the safety boxes for the truss movers done as all the components necessary for them arrived. I made sure to check that they fit on the gantry itself, and they fit just as I designed them to which made me very happy.

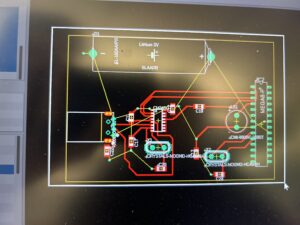

This week I also continued work on the water alarm PCB. I was able to finish the schematic. It took a lot longer than I initially expected it would. For the schematic I had to add a new component that converts USB to serial data. This allows me to communicate with the PCB and upload code to it from my laptop. In addition to this, I was able to get a large part of the layout of the PCB done. This task was very tedious as I had to find the right places to put components to ensure that no wires crossed over each other as that would make the PCB function incorrectly. I’m hoping to get the PCB as well as the components ordered early next week.

I did quite a lot outside the internship this week. I went to a Rockies game with my uncle and my cousin on Sunday. Sadly, the Rockies lost by a landslide, but it was still fun to hang out with my family. I also went on two mountain bike rides. One of them was at North Table trail center and the other was at Apex Park. And finally, I went and saw a Drum Core International performance in Fort Collins. It was incredible to see the bands in person as I’ve only ever seen them online in videos.

There are no comments published yet.