Hello! This was my third week researching at University of Houston under mentorship of Professor Baldelli. Last week, I was experimenting with different drops of Silane to see the trend of contact angles as I increased the drop count. I ended up finishing all but two experiments which required ten drops of Silane.

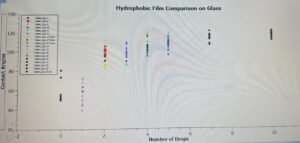

Transferring my work from last week to this week, I began with those two experiments, following the same procedure and acquiring contact angles to compute into SciDAVis with the other seven experiments. After entering my data into this platform, I found that there was a steady increase until it started to level out and remain constant from seven drops to ten drops. Presenting this to Professor Baldelli, he told me he expected to see that trend and instructed me to use one of my samples with seven drops of Silane for making the Polydimethylsiloxane (PDMS) stamp because the difference between seven drops to ten drops was very small.

For the next couple of days, I learned how to make a Polydimethysiloxane (PDMS) stamp, which took a total of five trial and errors before achieving a cured stamp worthy of being used to ink gold with Octadecanethiol (ODT). This was very frustrating to me because of how eager I was to progress in my research with a glass substrate, but I quickly recognized that my experiments aren’t going to be perfect at first and I’m still learning a lot while having fun, which matters most in an opportunity like this. Four of the five trial and errors are as follows:

For my first try shown below, I put the petri dish with the mixture of uncured PDMS and glass substrate in the vacuum desiccator for twenty minutes, then transferred it to the vacuum oven without heat, only suction, for one hour and then with heat (60 degrees Celsius) and suction for another hour.

I cut, with a razor blade, around the imprint of the glass substrate after breaking the full, hardened PDMS out of the petri dish and peeling the glass away from the stamp. As you can see, there are a few bubbles on the surface of the stamp as well as small bubbles inside the hardened PDMS so this will not work for the inking process; there are too many impurities that could affect the clean print of ODT on gold.

For the next two tries shown below, I put them in the vacuum desiccator for twenty five minutes and then the vacuum oven with the suction working simultaneously with heat. The second sample I put in the vacuum oven under the described conditions for an hour and the third sample I left in the vacuum oven overnight. The temperatures were kept constant for both tries at 70 degrees Celsius.

Second sample

Third sample

Before trying a different procedure, I tried the same process again and ended up getting this:

However, about halfway through of doing both suction and heat for an hour in the vacuum oven after the vacuum desiccator, I remembered I forgot to transfer the PDMS mixture to the petri dish containing the glass substrate. I decided to let it go for the full hour to see what happened and it ended up working perfectly.

When transferring the PDMS to the petri dish with the glass, I put a small dot of the mixture underneath the glass to stop it from moving around when I pour the rest of the PDMS over it and while it cures. The whole point of curing the polymer is to degass it under a vacuum so you can create a stamp with the hydrophobic Silane film from the glass on it and add a thiol otherwise known as the “ink” onto the smooth and pure surface afterwards. Instead of bubbles rising to the surface and popping immediately, the small dot of PDMS under the glass kept supplying gas to the smaller bubbles on the surface, which added volume instead of popping them. The hardened polymer without the glass substrate cured completely because there wasn’t a catalyst supplying gas instead of degassing the mixture.

By my sixth try I was able to get a clear and hardened stamp by throwing the mixture of elastomer base and curing agent (which creates the PDMS) in the vacuum oven with just heat (at 60 degrees Celsius). After two hours of being in the vacuum oven the PDMS was fully hardened and ready for the next step in my research.

The last thing I did this week was pattern Octadecanethiol (ODT) on gold through a stamping process. Octadecanethiol is used as a monolayer ink that casts self-assembled monolayers (SAMs) on the surface of gold.

To prepare the ODT I mixed a ratio of Ethanol and Octadecanethiol powder.

I pour some Ethanol in a beaker and dab the powered ODT into the tip of a pipette, making sure that when I mix the pipette into the beaker containing Ethanol I get all of the powder out. In order to dissolve the ODT powder in the Ethanol you put it in a machine that uses sound waves to mix the solution.

Then, I take another pipette and disperse the Octadecanethiol solution onto the stamp about three or four times, evenly coating the surface area of the stamp. I immediately follow that up by “drying” the stamp with nitrogen gas.

After that, I stamp my PDMS sample on a freshly cleaned with Ethanol piece of gold. The important part of this step was to determine how much time produced the best contact angles before they started decreasing. I did ten seconds, five minutes, ten minutes, and fifteen minutes.

The mean contact angles of the left and right side:

- 10 seconds: Left —> 99.4 degrees; Right —> 99.0 degrees

- 5 minutes: Left —> 121.1 degrees; Right —> 120.5 degrees

- 10 minutes: Left —> 114.1 degrees; Right —> 111.0 degrees

- 15 minutes: Left —> 75.4 degrees; Right —> 75.8 degrees

Results:

After applying the ODT to the gold (which makes a hydrophobic film on the gold) I found that the contact angles increased until five minutes, then, slowly started decreasing after that time.

Instead of moving on to the next step I wanted to know at exactly which time this transition of increasing to decreasing occurred, so I did two more stamps. One six minutes long and the other seven minutes long:

- 6 minutes: Left —> 120.3 degrees; Right —> 116.1 degrees

- 7 minutes: Left —> 86.4 degrees; Right —> 84.0 degrees

With these results I concluded that five minutes of pressing the PDMS stamp onto the gold gave me the best contact angle measurements.

Outside of research this week, and mostly not for fun, I dealt with a water damaged, green screened phone—from walking in a Houston rainstorm—that was still able to send my watch notifications and set my alarms off…alarms that went off at 11:00 pm even though I didn’t have one set for that time! Luckily, I was able to receive a new phone the very next day after having a grad student that works with me take me to a Verizon store!

Besides from feeling like I would be disconnected from my family for three weeks if I didn’t get a new phone sorted out (thankfully I did), I was able to attend an orchestra concert that gathered college students from around the United States to play in the Texas Music Festival (TMF).

There are no comments published yet.