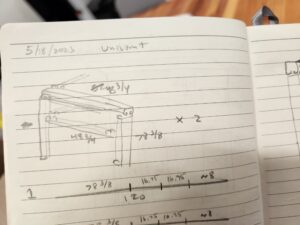

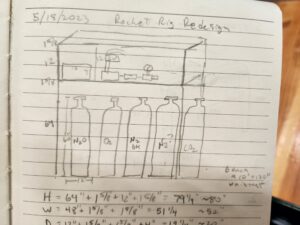

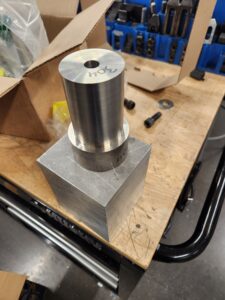

I’m TJ Neumann, and this summer, I am working in the CU Boulder Aerospace Machine Shop, where I am learning from several expert machinists on how to fabricate, design, and build advanced parts. I am learning how to use many different machines, including, but not limited to, a knee mill, a 3-axis CNC (computer numerical cutting) mill and a toolroom lathe. These machines will allow me to fabricate things with a high level of precision and solve problems I am presented with. In addition to learning how to use these machines, I am also helping to fabricate parts for the different labs in the building. I have so far begun to fabricate a base and housing for a set of sensor equipment, a rocket motor test bed, and a tube for testing the effects of electric current on specific types of gases. In doing these projects, I have learned how to understand and work with the requirements provided to me by the labs, so that I can give the best advice possible as to how they can make their parts feasible to machine in a short amount of time, as well as learning how to use the necessary machines to create the parts. I have also helped my mentor work on his bike, which he has added a lawnmower motor to. I helped add exhaust tubing and I helped to fix the motor mount, so that the drive chain would be taut and work effectively. I also help around the shop with maintenance and I help advise the students who come in to work on projects. Some of the maintenance I have done is bed leveling on a CNC mill, which involves cutting off the top laver of the bed with a tool the size of my hand, spinning at several hundred RPM.

This past week, I also had my birthday, along with my host mother and my dad. We went out as a group to go get Thai food and cake, as well as open presents, which was fun. The week was fairly dreary, so there were very few opportunities to go outside and take advantage of some of the fun opportunities in Boulder, but I used that time to begin work on my personal machining project. My personal project is to create a yoyo in the machine shop. I will be using the milling machines and lathe to cut a yoyo out of 7075 aluminum and stainless steel. This will require me to use Solidworks to design the yoyo, so that I can make the yoyo accurately and correctly. I am very excited to continue my internship and keep learning more and doing real work that can help people!

There are no comments published yet.