I spent my weekend with some friends who live in the area and we had an amazing time playing ultimate Frisbee and just visiting with each other. However I came back Sunday evening ready for the week ahead.

On Monday Morning we went to our meeting (Tom brought muffins because he is awesome) and James and I talked about the problems we had been seeing with Battery Pack 3. Tom said that we should put together a presentation and present to everyone on Tuesday morning. So James and I took apart Battery pack 3 and took each individual cell and drained it and watched to see at what voltage the MOSFET activated because we were pretty sure that one faulty MOSFET was causing the problem on the whole board. Strangely enough in our eyes every cell dropped to about the same level before the MOSFET activated showing that nothing should be wrong. With almost nothing to take from the tests James asked me to put together a power point presentation including graphs from both Battery pack 2 and Battery pack 3. I finished the power point late that afternoon then went to a bouldering gym with a coworker.

The Next day James and I presented the PowerPoint I made to the whole team including Tom and Rick Kohnert who is also a professional working on the project. One very important piece of data was that the MOSFET on battery pack 2 activated at 8.56 Volts opening the circuit but the circuit closed again when the Voltage fell to only 8.45. The MOSFET on battery pack 3 however activated at 8.66 Volts but didn’t reactivate again until the voltage fell all the way to 8.18 which is well below the operating Voltage of the solar panels. Tom hypothesized that when current on the power supply reached 2 amps the power supply could suddenly give more voltage (because the power supply can only give a certain amount of power P=VI when the I dropped the V could spike before it was regulated) and this voltage spike activated the MOSFET in battery pack 2 which was never deactivated to close the circuit because the Voltage never fell below 8.18 V. We decided to order new batteries because the Solar panels never operate at or below 8.18 V so if the MOSFET activated on these batteries we would lose the entire satellite.

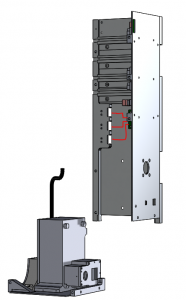

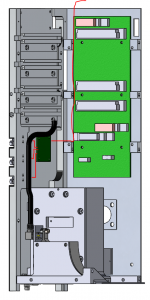

Two pictures I “took” of the 3D model in solidworks. These will both be used in the assembly plan.

On Wednesday we had our normal morning meeting and the main problem that had also been present earlier in the week was that the machine shop, which is where a lot of the parts of the satellite including the walls are being built, told us that they needed the 3D solidworks model of our parts but also drawings. Which sounds simple but its actually fairly complicated. Bena, Sid and I all went down to the machine shop to talk to someone about how exactly the drawings should be made. When we got back to the office Bena and Sid went to work on the drawing and I started to do even more work on the assembly plan. This included creating a table on every page that had the instructions for what you are supposed to do on that step and a sign off to ensure that someone does that. If there was bolting involved in that step which many did involve bolting then I also had to include the type of screw, type of hole it went into, the size of the screw, the length of the screw, the desired torque for the screw and a column to record the actual torque. I am currently still waiting on a chart that will help me determine the desired torque for each individual screw. This took a really long time and I didn’t even finish on Wednesday. That night I went and met a friend from Ridgway who was in Boulder for a camp. We got cheesecake and had a great time.

Thursday was a pretty slow day compared to everything before it but nonetheless enjoyable. I spent most of the day finishing the current version of the assembly plan (although I’m sure it will be revised) and making sure that we were ordering enough and the right screws for the assembly. I also spent some time charging and checking the fully charged voltages of the batteries that we received that day. That was pretty much all I did that day which doesn’t seem like a lot but really tired me out.

On Friday morning I went with James to his friends PhD defense. It was about precipitation of charged particles from the outer magnetosphere and that’s that’s all I would feel comfortable sharing because a lot of very large words were used. This was actually really cool to see even though it was such high level stuff. I then set up some batteries to charge with James before watching Bena as she attached some deployment switches to the EPS baby board. This was cool to watch because she was basically putting components onto a circuit board that would be used in flight. What the deployment switches do is when a pin holds these spring loaded arms down it opens the circuit they are attached to. So what happens is so nothing is running while the satellite is still on the ground these pins are inserted and have red tags on them that say “remove before flight” so no one forgets about them. Then when the cubesat is placed into its launcher the deployment switches are held down by the launcher so nothing start operating in the rocket. Then the pins are removed so that when the cubesat leaves the launcher the spring arms close the circuit and allow the satellite to turn on. I thought this was super awesome and I was glad to see such an important thing being done. That wraps up my second week at this amazing place and you will be hearing from me next week.

(Note: Header photo not completely relevant but still super sweet.)

There are no comments published yet.