My name is Marten Kendall and my internship is in our very own state of Colorado in Boulder at the Laboratory for Atmospheric and Space Physics (LASP) at the University of Colorado Boulder. I will working on the Miniature X-ray Solar Spectrometer (MinXSS). This is a very small sized satellite known as a cubesat. There are different classifications for these satellites. The “normal” cubesat is 10cm x 10cm x 10cm. MinXSS however is a 3u cubesat which means it is 10cm x 10cm x 30cm. This project has been going on for over three years now with a very broad spectrum of people working on it including college students and professionals. I’m working under a few people including Tom Woods and Xinlin Li who are very high up on the chain of command on this project and I am even more directly under James Mason who is a student working towards his PhD. Everyone who I have met to date here have been incredibly helpful and friendly. Before I arrived I did not think that I would be doing very much actual work on the project and would be more of an observer. However everyone here has done an incredible job of getting me involved in as much stuff as they can. Another thing I was worried about was the highly competitive field of new sciences. I thought that I would not be able to write about or take pictures of many of the things I would be doing here. It was not soon at all however before I discovered that I could not have been more wrong. Because this project is being done through a public university and almost all of the funding is coming from NASA which is a branch of the federal government so they encouraged pictures and for people to share what they are doing. All of the data this satellite collects will also be available to the public soon after it is collected. So with all of that out of the way I can start talking about the cool stuff.

If you would like to read the full proposal for this project I attached a PDF below. The main objective of this mission is to get more accurate readings of Soft X-rays(SXR) emitted from solar flares between .04 and 3nm. Many observations of this SXR have been conducted but all have been very low resolution and did not give enough information on a small enough scale to come to a concrete conclusion. With more precise tools we can determine where in the ionosphere, thermosphere, or mesosphere this energy is being deposited. This information is very important to understand solar weather and how it effects the earth and it has never been recorded before. Probably the most important tool on MinXSS is the X123 which will be the tool that actually measures the wavelength of the SXR.

This is an image of Tom Woods who was working on applying thermal foam to the X123.

This is the overall goal of the mission but we have many other things to work on with the satellite that do not seem like they are directly related to that goal. The first day I arrived I was given a tour of the LASP grounds and a brief overview of some of the missions they have been a part of in the past. LASP’s predecessor the Upper Air Laboratory (UAL) was founded in 1948 a decade before NASA even existed so they have plenty of missions both successful and non-successful to talk about. He showed me rooms that are involved in all steps of the rocket/satellite process including various clean rooms as well as vacuum chambers, assembly rooms, the control room for their satellites, and of course the lab where MinXSS is being worked on. One of the reason that you need to use a clean room to make the parts for the satellite is that if there is water in the air it will get into the circuits and whatnot which isn’t a problem for the operation of the circuits because obviously your computer still works in Florida where it is humid beyond belief. The problem is that when the satellite gets into space that water will leave the space craft and float around it in the same orbit as a space ice dust cloud that will mess up all the measurements. This phenomena is known as out gassing and happens not only when water gets in the system but also happens with a lot of building materials notably most plastics. For this reason almost everything, with the exception of some plastics that are known not to out gas, on the satellite is made of metal. Another huge problem working with delicate circuitry is that the static electricity from your hands will decimate a board. For this reason we wear special blue coats that keep static electricity on our body and when working with stuff that is prone to this problem we wear bracelets that ground our bodies making it so they don’t discharge into the board.

That same day I helped James run some very strenuous battery tests. I say strenuous meaning even more thorough than you would think you would need for a satellite because MinXSS will actually be going to the International Space Station (ISS) before it is put into it’s own orbit. Because these batteries will be on the ISS with a bunch of humans we were given a set of tests that we needed to do on the batteries to make sure beyond any doubts that they would not end up killing people in space. These tests were supplied by a company named nanoracks which will be bringing MinXSS into space. The tests include a full cycle meaning fully charging then discharging then charging then discharging then charging again. This cycle alone takes 25 hours. This needs to be done a total of 4 times along with an overcharge test, an over discharge test, short circuit procedures (meaning purposely short circuiting the battery) and both a vibration and a vacuum test. Everything on a satellite also has a backup in case something fails before launch so we have to do this for three sets of batteries. I helped with a small portion of this test but it will be ongoing into next week. The main thing that James and I were testing when we did the tests was this incredible chip known as a MOSFET. This stands for Metal-oxide-semiconductor field-effect transistor. Although I cannot tell you exactly what that means I can tell you general what it does and it’s use on the batteries. A semiconductor is a substance that based on some laws of quantum physics easily conducts in some situations and does not conduct electricity under other circumstances such as where leads are placed or temperature for example. With this technology the MOSFET in the battery can conduct electricity and allow the battery to charge to a certain point before a sensor realizes that the battery is being overcharged then without any moving parts uses the semiconductor to open the circuit and stop the battery from blowing up. James and I made sure this was functioning by attempting to overcharge the batteries and recording when the MOSFET stopped us. The MOSFET worked and opened the circuit when the battery reached 8.66 Volts which was .26 Volts higher that the “maximum”. This was acceptable and the batteries passed that test.

Doing a charge cycle on a Battery Pack.

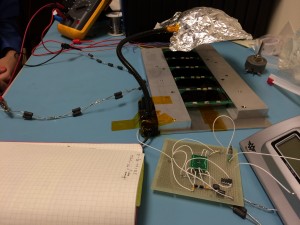

The next day most of the team met in Dr. Wood’s office for our daily meeting discussing tasks for the day as well as problems that may have come up in previous days. One objective that I helped with was partially integrating one of the battery packs. We could not complete the whole pack because we were waiting on heaters that go between the batteries. I was given a small lesson in soldering and the technique I should use for the specific task then I soldered two temperature probes to wires that will go between the batteries and help us make sure the batteries don’t get too hot or too cold. I then also helped create a chain of resistors (which you can see in one of my pictures) that was to be used to help test a Peak Power Tracker (PPT) circuit that was to be used with the solar panels. The PPT is a circuit that solves a problem with the solar panels in which you need both current and voltage to have power coming from the solar panels (Power = Voltage x Current) but the solar panels were flipping between max voltage with no current and max current with no voltage. In order to fix this we built a circuit that uses resistors to regulate the current of the solar panel always keeping in in the range where the maximum power is output. Due to .75 ohm resistors instead of 75 ohm and magical resistors that somehow broke physics and were acting like diodes we were not able to finish the testing that day.

Testing the PPT with an iridium lamp.

On my third day we were told that the radio for MinXSS was up and running and that with a few more tests it could be permanently attached. Bena, Christina, and I then started to do the testing on the PPT circuit. We did all of our controls with normal resistors and everything seemed to be working fine. Then we attached the PPT board and everything essentially stopped working. We were baffled until Bena realized she had used some of the bad resistors in the PPT board so we were delayed on our testing once again. I spent the rest of my day working with a programming language called IDL. I have some experience doing coding in languages such as C+ and C but I was not familiar with IDL. It is a thousand times more user friendly than the C languages and I have been told that it is the closest to “talking to a computer” you can come by. I used a program that was written by Dr. Woods and Christina to change the raw hex data from the battery tests into something actually usable then I wrote a program in which I selected a file from a huge dump of data from the battery tests and it was turned into graphs which I saved to later be put into the report for Nanoracks. This sounds very simple but anything involving code takes exponentially longer than you would think. I also then ran into a problem in which the software used to record data was updated so I needed to use a different program to “decode” the hex. However something wasn’t working right, Christina couldn’t figure it out and Dr. Woods was either in a meeting or had gone home so we decided to call it for the day.

The fourth day that I was there I discovered that the problem I thought was with the code was actually faulty data. I then finished writing the code that created and saved the graphs then finished making the graphs for all the battery testing data to date. Later that day we could not to the PPT testing because it was too cloudy out so James and I worked on the Battery testing. That day some of the tests came back very strange on Battery pack three and we could not get them to function properly so we decided to bring it up at the next morning’s meeting.

The next day we all arrived for our meeting before a assembly review and decided to try and test the PPT while we had time and sunlight so we raced outside and set everything up only to find out that the PPT was wired wrong. We then decided how to fix it and went inside for the assembly review. This consisted of James, Sid, and Bena (The three people I directly work with) going through their plan for the assembly of the spacecraft in front of four people with doctorates and experience with satellites. It turned into experts arguing over the finer details of how to assemble the satellite. After this two hour process the entire portion of LASP that works on solar studies went out to lunch at a restaurant in Boulder called the Southern Sun. I had a great time and Tom Woods very graciously paid for all of the students that came. I spent the rest of my day after lunch editing my code that created the graphs for the battery test, making some new graphs with the new code and then adding a large amount of the graphs to a document that will sent to NASA and NanoRacks to ensure the batteries met specifications.

While I have been here I have been exposed to some really cool stuff such as 3D printed metal hinges. They need very specific hinges that they could not buy from anyone so someone on the team named Bena Mero designed hinges in a software called solid works. These “plans” were then submitted to a company that printed them. The 3D printing process for metal is amazing because they use a metal dust that is laid based on the plan then heated up to a very high temperature with a laser before it cools and becomes solid.

3D printed hinges designed by Bena Mero.

I have been having an amazing time so far and although I am close to home compared to the other interns I have been living by myself in an apartment which has made me feel more independent than ever before. This first week has far exceeded my already high expectations and I cannot wait to see what else is to come.

thumbs up marten i am proud of you

Wow Marten! Amazing work you’re doing. I’m completely astonished at your level of competence in physics and the sciences in general. What a great experience to learn more and be working with such accomplished individuals. This is very cool stuff and I’m eager to hear more about it as it unfolds. I happen to have a fairly complex battery system in my basement that’s operating on an AC/DC converter box to run the sump pumps. Just the other day, I had to trouble shoot why I was getting a “no power” reading on the box when all the overhead lights, circuit breakers and fuses were checking out fine. After spending 4 hours jerry-rigging a bypass system it turned out to be an incredibly simple problem of the GFI popping on the electrical outlet. Stupid me for not noticing that first before I went to so much trouble. I also have several 12 volt batteries on constant charge in that same basement and sometimes worry that they might blow up one day. I hope not! In any case, I get that batteries and their systems can be complicated but can’t imagine working on something so important as the batteries for a satellite going into space. Really, really proud of you and all your accomplishments. Looking forward to more blogs and new discoveries.

All the best,

Alison

I am so proud of you, even though I have no idea what you are doing. Big hugs and kisses

Wow!!!!!!! Can’t begin to fathom the programming language you are into Marten. You are traveling in some interesting dimensions! Onward!

You have gifts my dear. Not only do you understand the technology you are working with, you are able to communicate your actions to others in an interesting way. Love you!